|

|

| THE ADVANTAGES OF USING MIRKA'S NET BACKED SANDING DISCS ARE IMMENSE! |

|

If you are in the sanding game, you may already know the effect that Mirka's net-mesh technology has had upon our industry. For those of you that are either new to sanding or have not yet heard of Abranet, Abranet Soft, Abranet Heavy Duty, or Autonet... read on!

|

|

|

|

|

|

|

Mirka's Net Mesh Technology has offers many advantages, including an ability to minimize dust in the work environment.

|

|

Abranet Soft is available in several grades, ranging from 320 to 2500 grit. One disc line can cover virtually any task.

|

|

|

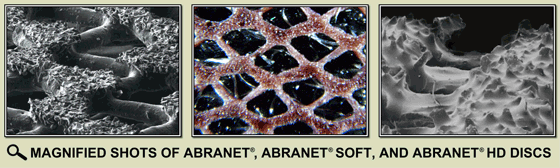

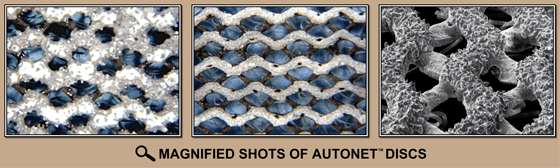

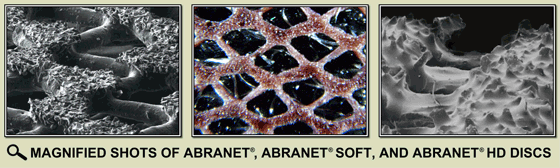

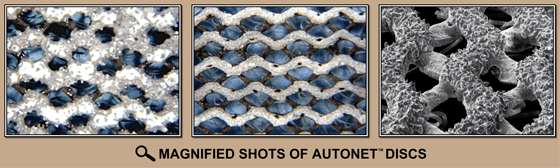

Traditional sanding products typically use paper as the backing to which the abrasive grains are attached. Instead of paper, Mirka's net-mesh products feature a strong yet flexible polyamide or nylon fabric. The mesh material is constructed using a crisscross net pattern (think of a tic-tac-toe board, and you'll get the idea). The abrasive particles are attached to the mesh, essentially creating a net of abrasive that can easily contour to complex shapes. Depending upon the application, a thin net may work better than a thick net, or vice-versa. Mirka addresses this predicament by offering net-mesh products in several variations.

Regardless the disc you choose, net-mesh technology offers many benefits. What do I believe to be the most surprising benefit among the many? How easy the discs are to control! Whether used by hand or machine (low or high speed), net mesh discs stay planted to the surface, even when used with liberal amounts of liquid. Try that with a traditional film-backed disc!

Although net-mesh discs don't utilize the sheer quantity of abrasive particles that film-backed discs employ, the results speak for themselves. By eliminating the solid backing and replacing it with one featuring thousands of openings, dust is swept from the surface, or vacuumed away altogether. Sounding good so far? We're just getting started!

|

| ––––– "IS IT JUST ME, OR IS IT DUSTY IN HERE?!" ––––– |

|

|

|

|

During one of our projects, my friend Larry was able to exhibit the benefits of dust-free sanding, without even realizing it! Mirka’s net mesh technology can help to eliminate dusty environments such as this. But then, guys like Larry wouldn’t have the opportunity to wear those uncomfortable (yet surprisingly chic) respirator masks

|

|

A clean work environment can really make a difference in the quality of the finished product. For starters, the sanding surface is easier to see, and knowing when a satisfactory result has been achieved is somewhat important, right? Sanding discs are much more effective when they’re clean, and last longer, too. A clean environment is pleasing to work in, and less fatiguing to boot! Finally, less time is spent doing dasterdly cleanup work, so more time can be spent completing the task or moving on to other things.

The simplest way to remove debris? Vacuum it away! There are oodles of machines available that are vacuum capable. Some machines are able to create their own suction (referred to as self-generated vacuum, or SGV), storing the collected dust and debris inside an attached dustbag. Other machines connect to a hose, which is attached to a vacuum. These are all great options, but not all machines are vacuum capable, and not all sanding projects can be tackled using a vacuum system (wetsanding comes to mind). Some people simply have no desire to employ a vacuum while sanding because dusting may be minimal, or the hose too cumbersome to bother with.

|

|

Vacuums are available in all shapes and sizes. This unit offered by Mirka is a perfect fit for this type of work. Paired with a random orbital sander, dust is virtually eliminated from the work environment.

Whether the job requires dry sanding of paint, wood, drywall, body filler, fiberglass, or even plastic, a vacuum helps to improve overall sanding results.

|

|

As the motor spins, machines such as Mirka's ROS650SGV create suction while you sand. The accumulated dust and debris are stored in the attached bag. Higher operating speeds create more suction.

What a difference a vacuum and net mesh discs can make!

|

|

|

The next option is to clean the disc, and to do so frequently. Coarse-grit discs can be cleaned using a rubber-based sandpaper cleaning block, which are widely used to spruce up the belts and discs used on tabletop machines. These blocks are not commonly used in my area of expertise (automotive post-paint wetsanding), but are otherwise a mainstay in the industry. A blast of compressed air aimed directly at the face of the disc works well, too. Once its been cleaned, a visual inspection of the disc will identify any remaining stuck-on contamination, which can be removed via agitation with a soft nylon bristled brush, a towel, or a wooden toothpick.

|

| ––––– PILLS, PIGTAILS, & CURLIQUES... I KNOW THAT SONG! ––––– |

| |

|

One of the biggest roadblocks on the path to achieving great sanding results are discs that have become laden with debris. As abrasive particles grind material from the sanding surface, some of the resultant residue migrates away from the disc. Oftentimes though, a portion of the debris becomes trapped between the disc and sanding surface, forming tiny spheres of abraded material as it rolls about.

Lacking an escape route, the spheres are flattened, and inevitably stick to the disc. This occurrence is referred to as pilling because the formations resemble tiny little pills (and you’ll need some after you see the damage they can cause). Although most sanding discs utilize coatings to minimize residue build-up, pills easily form and attach to the disc. Once stuck, they are hard to dislodge, especially if the material is sticky or tacky. Not good!

Pilling can ruin an otherwise perfectly refined surface, creating curlique-shaped gouge marks known as pigtails wherever they go. To minimize pilling & pigtailing, inspect and clean discs often. While you’re at it, be on the lookout for abrasive grains that have detached from the disc. Keep an eye open for tears, wrinkles, & worn spots on the disc face, too.

Mirka's net-mesh design minimizes the propensity for pilling because abraded residue and other contaminants can easily migrate away from the face of the disc and into the void areas of the mesh, keeping the abrasive face of the disc debris free.

For those of you that primarily use fine-grit discs to wet or dry sand freshly sprayed automotive paint prior to machine polishing- be sure to check the disc often, as catalyzed paints are notorious for being a bit tacky if the paint has not fully cross-linked (or cured). Those pesky little paint pills can really ruin your day- as well as an otherwise perfectly sanded paint job!

|

|

| - Click to Enlarge Images - |

|

|

| |

| ––––– IT'S WETSANDING, NOT WATER SKIING! ––––– |

|

|

If you've ever wet sanded with a machine using anything more than a very slow speed setting, it's very likely that your sanding disc rode upon a layer of liquid rather than the sanding surface. It's a phenomenon that is similar to the hydroplaning effect which occurs when we drive too fast on a wet road, and the tire is not able to displace the water beneath it. Mirka's net-mesh technology can virtually eliminate this problem.

When an appropriate water or petroleum-based liquid is used in conjunction with machine sanding, oftentimes the disc willskim atop the liquid until it is either displaced or it |

evaporates. Since there's not a lot of friction-induced drag on the disc, its rotation speed ramps up. Oncethe liquid has diminished enough to allow the abrasive grains to contact the sanding surface, the disc makes contact with a "crash landing" type of impact. This results in gouging of the surface, which can be difficult to remove.

Mirka's net-mesh design allow excess fluids to migrate away from the sanding surface. In the case of Abranet Soft, the thin layer of attached foam can store and disperse liquid as needed. A quick rinse of the disc using the lubricating fluid (conveniently delivered via trigger bottle) cleans abraded residue or debris from the disc. Since the net face of the disc stays clean, sanding results are consistent, and disc-life is extended. |

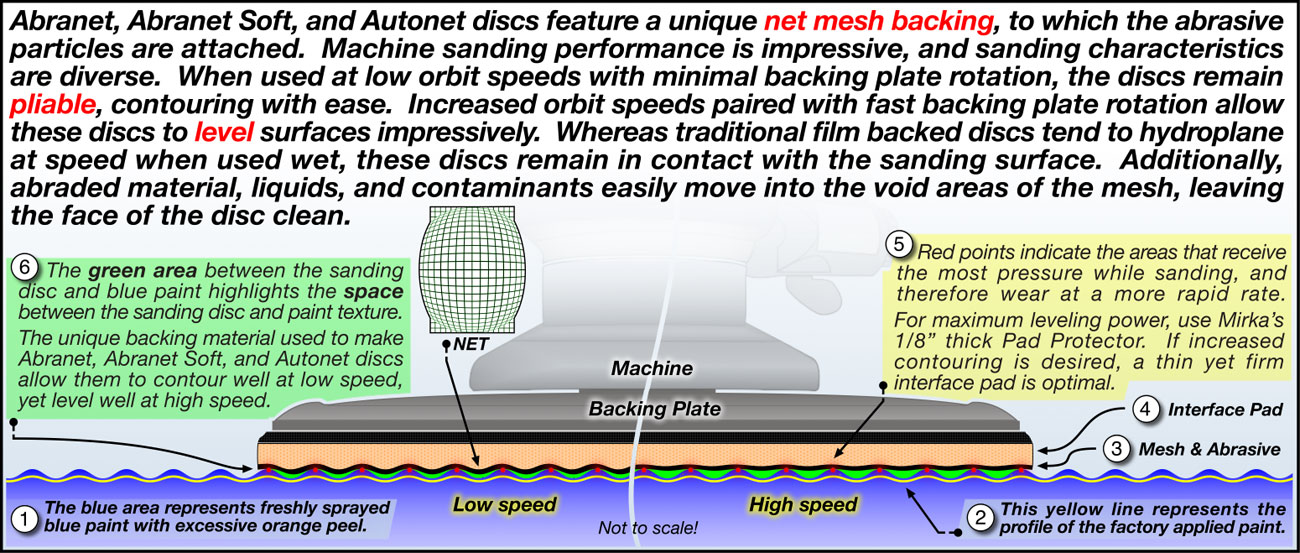

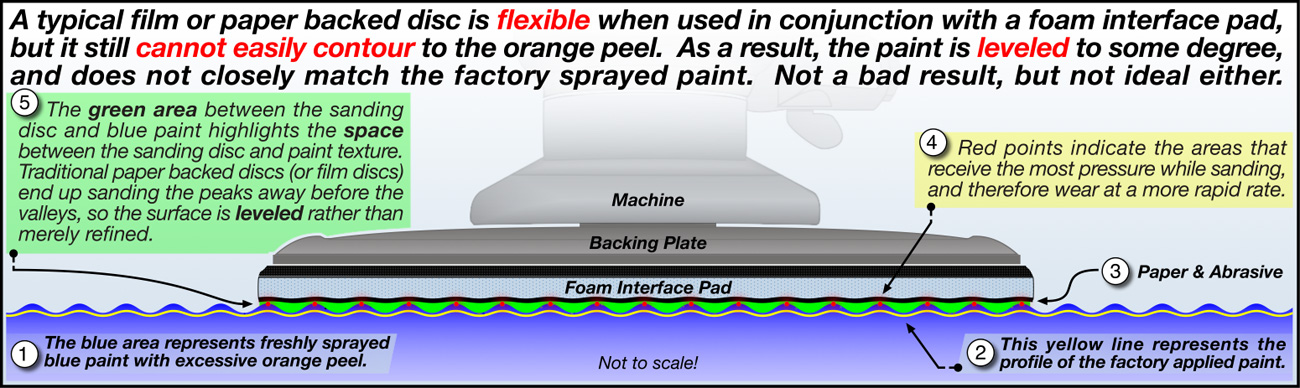

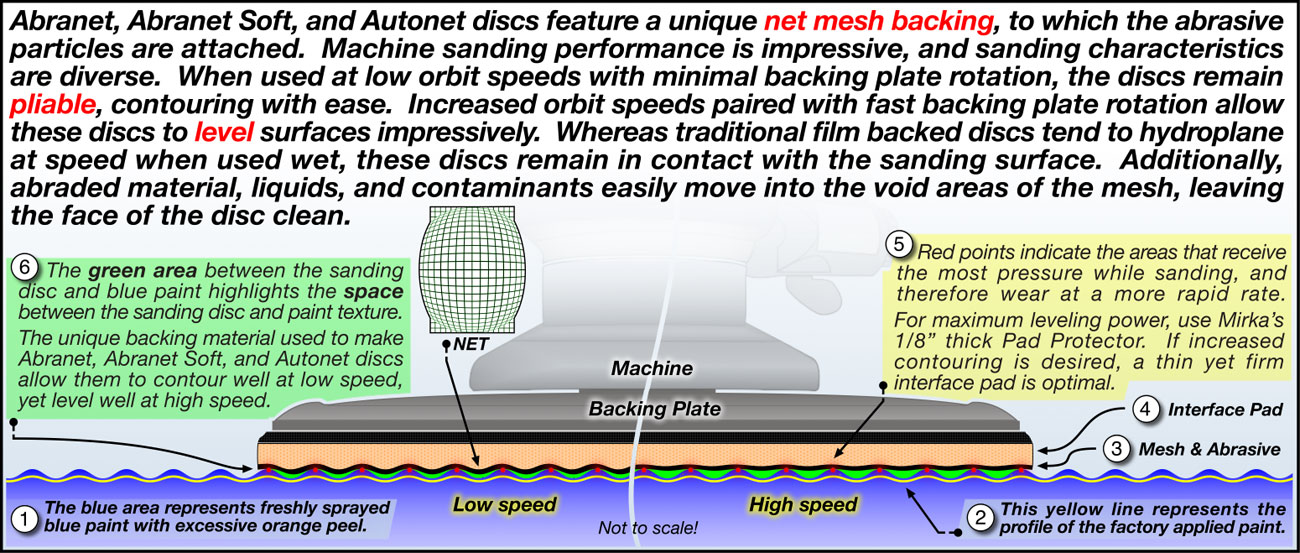

| REFINE OR LEVEL THE SURFACE... NET MESH TECHNOLOGY LEAVES IT UP TO YOU! |

|

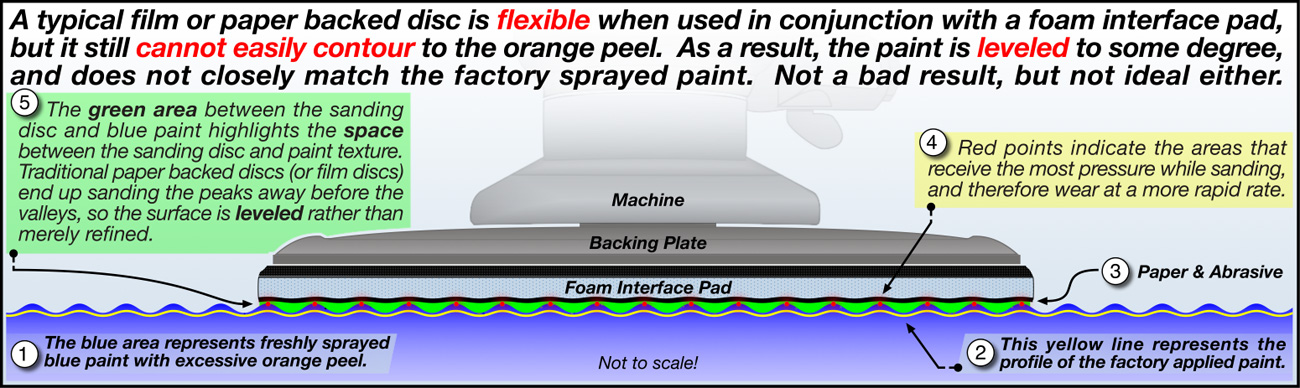

What’s the difference between refining a surface, or leveling one? Ahh, good question!

- If you wish to keep the intricacies of a surface intact, but need to sand it in preparation for a coating, polishing, or refinishing of sorts, you need to refine the surface.

- If your goal is to eliminate the peaks and valleys of a surface, thus making it “laser straight” or “mirror-like”, you need to level the surface.

|

For clarification, check out the diagrams below (click to enlarge images): |

| About net mesh discs: |

|

|

| About traditional film backed paper discs: |

|

Mirka’s net-mesh product offerings are diverse, and there are features and benefits to each particular type of disc. Interestingly, machine speed determines the characteristics of whichever net-mesh disc you happen to be using. In general, slower speed settings allow the disc to follow the intricacies of a surface more accurately than any film backed disc (thus refining the surface), while efficient leveling can be accomplished using higher speed settings. In terms of versatility, there are limits to how well any particular disc is able to impressiviely refine or level any given surface, but net-mesh discs far surpass the versatility of a traditional film backed disc. Whereas film backed discs quicky pack with residue (essentially losing contact with the surface at those points), net-mesh discs stay clean, allowing higher speeds to be a viable option to heavy duty or thickly-backed film discs. Besides- discs featuring heavy bcking (D, E, and F ratings) do not feature the contourability of a net-mesh disc, and they’re simply not available in finer grits (such as 600, 800, and up).

Perhaps it’s relatively easy to understand how net-mesh discs refine surfaces, but how can they effectively level surfaces, too? An analogy illustrating the point should do the trick. String trimmers are great for chopping grass and weeds, but what do they have in common with net mesh sanding discs? Nothing really, except the way they create leveling ability at high speed.

When the monofilament polymer string (the plastic string thing) is rotated at a high rate of speed, it cuts grass, weeds, and any other unfortunate thing that happens to get in its way. Eliminate the speed, however, and its cutting power is diminished or eliminated altogether. The laws of physics back this up, but no need to go there, since anybody that has used a string trimmer knows how quickly they can change a landscape.

Net mesh sanding discs use abrasive grains to grind surface material away, and lots of folks use random orbital sanders to complete the sanding job in a time-efficient manner. When used with a low speed setting, net mesh discs such as Abranet and Abranet Soft contour to the surface being sanded with ease. Autonet and Abranet HD utilize thicker backing materials, so they are not quite as pliable, but very good nonetheless.

A high speed setting generally causes the backing plate to spin at a rapid rate (6-10 turns per second is not unheard of). While we certainly cannot expect to chop surfaces away as the string trimmer does to grass, the net-mesh disc does gain cutting power the faster it spins, keeping the abrasives planted on the sanding surface in the process.

Of course, the amount of material removed by any disc is dependent upon the hardness of the material being sanded, the amount of pressure being used, machine speed settings, the size of the abrasive grit, the application method, and user technique. |

Net mesh discs can be used on a wide variety of surfaces, including:

- Automotive, airplane, and marine grade paints

- Powdercoat

- Metals (including steel, aluminum, copper, brass, and stainless steel)

- Wood

- Hard plastics (such as Plexiglas®, Lexan®, and other similar materials)

- Fiberglas®

- Corian® countertops (and similar materials)

We stock Abranet discs in 3" and 6" diameters.

Discs are available in: 80, 100, 120, 150, 180, 220, 240, 320, 400, 600, and 800 grit.

We stock Abranet Heavy Duty discs in 6" diameter.

Discs are available in: 40, 60, and 80 grit.

We stock Autonet discs in 6" diameter.

Discs are available in: 80, 120, 180, 240, 320, 400, 500, 600, and 800 grit. |

|

|