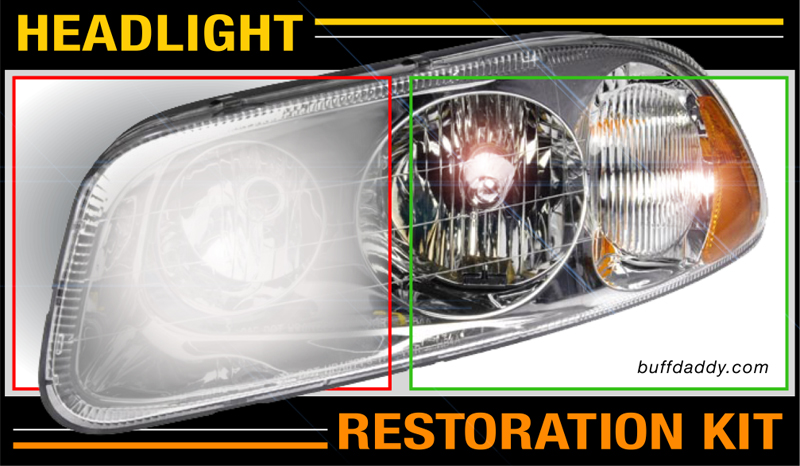

D.I.Y. Headlight Restoration Kit

|

|

| Click to enlarge image(s) |

Do It Yourself Headlight Lens Restoration Kit.

Piecing together the items needed to restore clarity to plastic headlight lenses can be confusing. To simplify things, we've gathered up the components needed to restore that like-new appearance, and listed them here.

All sanding components attach via Velcro-style hooks & loops. Kit includes everything needed to restore headlights via hand application.

• (1) Dome-Style Sanding Pad (holds Velcro discs and pads)

• (1) Interface Pad (improves sanding disc flexibility)

• (4) Coarse Sanding Discs (removes heavy-duty damage)

• (4) Fine Sanding Discs (removes sanding marks & mild damage)

• (2) Super-fine Sanding Discs (removes fine sanding marks)

• (2) Ultra-fine Sanding Discs (prepares for final polishing)

• (1) Liquid Compound/Polish (restores clarity to lenses)

• (1) Aerosol Headlight Coating (seals & protects lenses)

Add a Cushiony Interface Pad.

Add a Cushiony Interface Pad.If you plan to use the included Dome-Style Sanding Pad for tasks other than headlight lens restoration, consider adding a tall interface pad to your kit. This 3" diameter interface pad is approximately twice as tall as the included interface pad, and can be used to increase contourability of all Velcro-style sanding discs.

Add a Yellow Foam Polishing Pad.

Add a Yellow Foam Polishing Pad.To restore clarity, by hand or machine.

Velcro-mount, 3" diameter. To restore clarity by hand or machine. Fits the Dome-Style Hand Pad perfectly. Incredibly versatile & popular. Should be a staple in your pad arsenal.

For sanding mark removal, by hand or machine.

Velcro-mount, 3" diameter. For sanding mark removal by hand or machine. Features short-strand microfiber strings that deliver a rapid cut. A dense injection molded foam interlayer assists in delivering maximum machine motion to the microfiber material.

Add a Multi-Purpose Wool Buffing Pad.

Add a Multi-Purpose Wool Buffing Pad.All purpose pad removes defects & restores clarity, by machine.

Velcro-mount, 3" diameter. For sanding mark removal, and to restore clarity, by machine. Features dual-length strings that deliver a fast cut. A rigid blue foam interlayer assists in delivering a high rate of machine motion to the wool, while providing a cushiony and controlled feel during polishing.

If you would rather restore headlight lenses using a handheld drill, this 3" diameter Shaft-Mounted Backing Plate enables attachment of interface Velcro-style pads and sanding discs. Mounts into chuck-style drills.