|

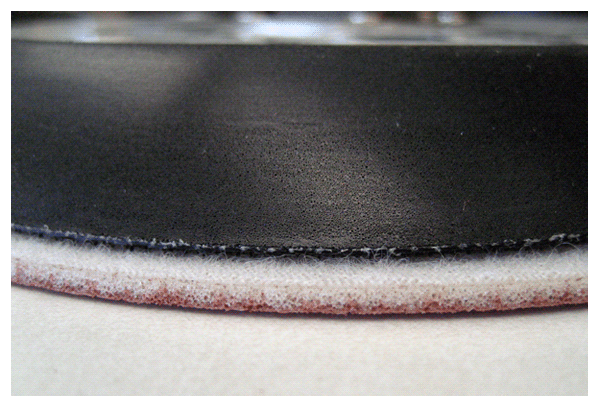

Interface pads can increase the flexibility of a sanding disc.

This comes in particularly handy for working on curved, complex, or delicate surfaces.

Interface pads help to evenly distribute pressure and machine action.

This is especially noticable when working on soft or delicate surfaces.

Interface pads can increase user comfort.

This is because the foam cushioning can absorb high speed vibrations and side to side lateral movements that are created by the machine. Occasionally, a tall or stiff interface pad will magnify lateral movement at higher operating speeds, with a movement is similar to that of seesaw. Fortunately, this is not a common occurrence.

The addition of an interface pad may or may not hinder leveling performance.

This assumes that the machine is being handled in a controlled manner. Unfortunately, it's not that easy to hold an oscillating machine completely parallel to a flat surface. This is especially true if the machine is outfitted with a stiff backing plate, or if the surface being sanded is inconsistently hard (or grabby).

The difficulty level rises if the machine is outfitted with large-diameter sanding discs, or if the machine is being operated at high speed. Considering these points, it is easy to see why the addition of an interface pad delivers a more consistent result for most folks.

Interface pads work well on flat surfaces, too!

Most sanding discs lack cushioning, so the backing plate must be relied upon to deliver contourability. When would cushioning or contourability be beneficial for sanding a flat surface? Almost always! Here's an example of a situation in which the addition of an interface pad would deliver a better result:

While machine sanding a painted panel whose surface is flat, you are inadvertently holding the machine off kilter. Due to edge-digging of the disc, uneven distribution of the machine’s eccentric motion, and concentrated areas of applied pressure, the surface is now chock full of low spots and gouge marks. Oh-no!

Installation of an interface pad can help to minimize these negative effects by increasing flexibility of the disc, and buffering any abrupt contact between the disc and the surface being sanded.

Interface pads can yield better control of the machine.

When sanding discs are used on uneven or curved surfaces, the combined interaction of the surface shape, backing plate rotation, and abrasive action of the disc cause the machine to wander in various directions. This is troublesome and unsettling, but can be downright scary when it happens at high operating speeds. An interface pad can alleviate uncontrolled wandering by increasing flexibility of the disc, and distributing pressure across the face of the disc in a more consistent manner.

Interface pads can alter (or soften) a machine’s action.

This can be a plus if you’re in need of a gentler action, or a drawback if you’re wanting maximum backing plate motion for a given speed setting. How much can an interface pad affect machine action? The answer to this question depends upon several factors, many of which are listed below. Keep reading to find out!

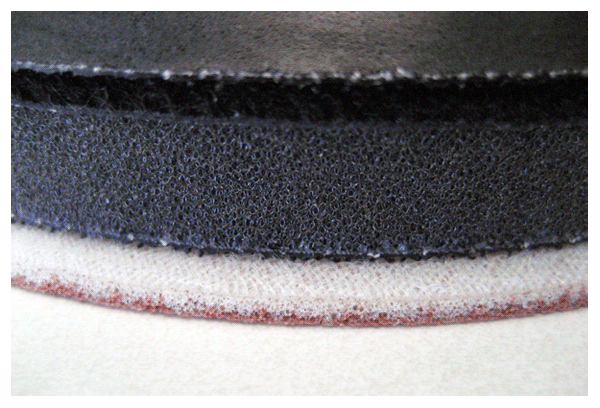

Characteristics of the foam and dimensions of the pad can really affect performance.

Squishy or pliable foam can twist quite a bit, which in turn converts motion into heat. This phenomenon effectively abates backing plate motion as the pad twists, oscillates, and turns. The net result? Less movement of the sanding disc.

The offset of the machine's backing plate spindle (machine stroke) is a big deal, too.

Whereas the action developed by a small stroke machine might be heavily affected when a tall and pliable interface pad is used, a large stroke machine may not. A simple consideration of pad cushioning versus machine stroke size dictates that if a machine moves the backing plate along a large circular path, it will not be affected to the same degree as a backing plate moving along a small circular path.

Random rotation of the backing plate usually slows with an interface, but not always.

Random rotation of the backing plate (and all things attached to it) may react to an interface pad in a surprising manner. Consider this; although a tall interface pad typically slows rotation of the backing plate, it is not a sure bet. The size, type, and shape of the abrasive grains attached to the sanding disc can grab ahold of the surface being sanding in varying degrees. This interaction between disc and surface is further complicated by panel shape and slickness. Application method also plays a part in this difficult to understand equation.

Orbit-speed and user technique combine to create ever-changing sanding results.

These parameters should be considered jointly because the user sets the machine speed (via speed dial), as well controls the amount of applied pressure, range of motion, machine angle (in relation to the sanding surface), and other aspects related to mechanical movements. A change in just one factor can dramatically affect sanding results. To illustrate this point, consider the effects of using a slow oscillation speed versus a fast one, and a light amount of applied pressure versus a heavy amount. There’s plenty of middle ground, too, but taking things to extremes tends to cover things pretty well:

- A slow oscillation speed paired with a light touch tends to transfer a machine’s motion from the backing plate through the interface pad fairly unscathed. Lighten the pressure too much, and the sanding disc will skim the sanding surface in an uneven manner. Dial in the pressure just right, and a nice result can be acheived. A light touch also keeps the random backing plate rotation speed relatively high.

- A slow oscillation speed paired with a heavy hand can dramatically slow backing plate rotation, or stall it altogether. Oscillation motion may be drastically altered, to the point of becoming so mild that is essentially useless. If the applied pressure eliminates cushioning altogether, the oscillation motion may closely mimic the original motion created by the machine, but surface gouging and disc failure is imminent.

- A fast oscillation speed paired with a light touch generally creates a leveled surface. Enough pressure must be used to keep the interface pad from fluttering. Otherwise, the fast-spinning, wobbling disc may cause edge gouging of the surface. When high speed fluttering occurs, a tremendous amount of heat is generated in the foam area of the pad because of the rapid compression, rebound, and twisting of the foam. Consequently, the attachment material may prematurely fail, the foam will disintegrate, or both.

- A fast oscillation speed paired with a heavy hand is not ideal because it seriously minimizes all reasons for using an interface pad in the first place. While this combination might deliver a satisfactory result if the interface pad was very thin or stiff, it should be used as a last resort.

|

|